A handmade bicycle is, as it reads, a 'handmade bicycle'. They are the opposite of ready-made bicycles made by mass-produced manufacturers.

They are handmade one by one by bicycle frame builders, who take into account the user's physique, riding style and intended use, and design them individually. This allows a bicycle to be made to fit the user. This is the biggest advantage and attraction.

In addition, the appearance of the frame, including the paintwork, can be customised to the user's preferred specifications. Of course, the parts assembly is also flexible. In other words, you can have a unique and irreplaceable bike that best suits you.

The history of global cycling is synchronised with the history of competition, with traditional steel-framed bicycles being used until the 1990s. And frame builders, too, valued their success in the racing world above all else. Today, however, carbon frames dominate the racing world and the bespoke, hand-made frames made by frame builders have disappeared from the highest level of racing.

In Japan, the unique culture of 'KEIRIN have made it one of the best in the world in terms of precision and quality, and we must not lose this valuable asset. The handmade bicycle has evolved out of the world of competition and is evolving into one that delivers even greater added value as a vehicle that enriches the hobby cyclist's bicycle life.

Tour de France.

The Tour de France is considered the pinnacle of bicycle road racing. Although carbon frames are now the mainstream, until the mid-1990s, hand-made frames made by European bicycle workshops were very successful.

When we think of these workshops, we think of Italian brands such as Colnago, De Rosa and Pinarello, which are still the top brands in the Tour. However, home-made French bicycles were also active, with French riders such as Luison Bobet and Jacques Anquetil winning the Tour in 1950. In particular, Luison Bobet (who won the Tour three times in a row in 1953/54/55) ordered a competition bicycle from René Hérse, a company with a famous image in Japan as a randonneur (excursion bicycle).

Frame builder.

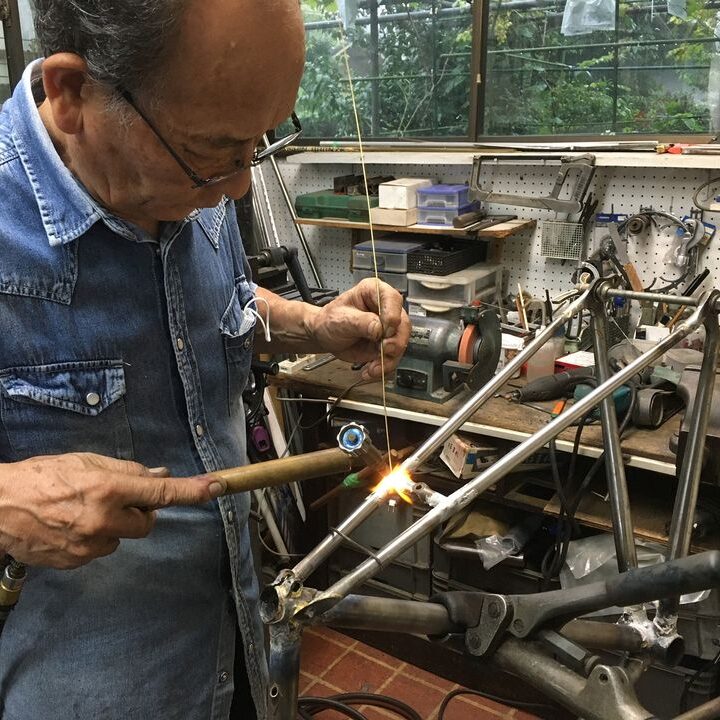

Craftsmen who manufacture handmade frames are called frame builders. They start by designing the geometry (dimensions of each part of the frame), decide on the specifications of the tubes to be used, process and weld the tubes and finish the welded parts. Even if the same tubes and geometry are used, different builders will produce a different riding experience. In other words, the builder's individuality becomes the brand's speciality.

Many builders train at a frame workshop before setting up their own workshop. In recent years, some builders have acquired basic knowledge at schools such as the Tokyo Cycle Design College before training at a frame workshop and setting up their own workshop.

It is said that there are currently nearly 80 bicycle workshops in Japan, where many frame builders are active.

KEIRIN

Japan is a handmade bicycle paradise, with many brands of handmade frames relative to the sports bike population. Part of the reason for this lies in KEIRIN. The frames that KEIRIN riders take on must be manufactured according to the standards set by the JKA, a public interest incorporated foundation that enforces KEIRIN, and the brand must be registered with the NJS (Japan KEIRIN Association).

Currently (as of 1 June 2020), 25 companies are registered, including domestic mass-production bicycle manufacturers Bridgestone and Panasonic, as well as private-scale bicycle workshops, making the steel frames that support the explosive power of bicycle racers.

The registered brands can be found on the following website.

http://keirin.jp/pc/dfw/portal/guest/data/bicycle/index.html

A handmade bicycle is unique to you. The frame builder designs the geometry (dimensions of each part of the frame) to suit the user's use, leg strength and riding form, the type and specification of tubing, the shape of the lugs, direct accessories and colouring are also flexible. You can have a bike that is unique and only one of its kind in the world. Furthermore, they are easy to repair and customise, so you can continue riding for a long time. This is another attraction of handmade bicycles.

The best part of handmade bicycles is the process of communicating with the builder, discussing and finalising the bike that the rider wants to build. Who is the right specialist for you? The first step is to find an expert. Then come prepared with a bit of material to discuss. Once you know how you want to ride, the builder will be able to get the words out of you and create the perfect bike for you.

Communication with the builder is never just about the onece building your bike. The paintwork has been scratched. I want to refresh it with a new coat of paint. A pipe has been dented or crushed and I want to fix it. Communication continues even after the bike is completed, for example, if you want to change braized-on accessories or specifications. By building a good relationship with the builder, you can keep riding your bike for a long time. Of course, it is also a good idea to actively participate in any events organised by the builder.

1. "I need to work out what I want my bike to be"

The process of working out what you want your bicycle to be may be painful, or it may be enjoyable. If the process is not clear, you will not be satisfied with the finished bicycle, even if you have spent a lot of time on a custom-made bike. Even if you don't have a clear idea of what you want, the frame builder will be able to organise your thoughts and guide you in the right direction during your conversation.

2. "It takes time to deliver."

First of all, communicate with the builder. This may not be done in one session. Take your time and be prepared. The production process, many builders do not build frames one by one, but often combine several orders and work on the same process at the same time. You might think, "Why not just have my frame made straight away?" but unfortunately that can be difficult.

If you can drop by the workshop, you might want to look in from time to time and ask, "How do you like my frame?" If you can drop by the workshop, it might be a good idea to take a look and ask them "How do you like my frame? It may be a process where you can tell them what you would like to change in case of any changes. The time until the frame is finished may be a time when you can rethink the specifications and so on.

After the frame has taken shape, it is time for the painting process. As many workshops outsource the painting to a painting factory, the time it takes to get the frame into your hands will depend on the factory's work schedule.

Delivery times vary from workshop to workshop. The shortest delivery time is often from one to three months, while many workshops require as much as a year. Be patient.

| How to ride/ bicycle type | Material | Parts order | How to order | Available langage | Delivery time | Reparir and repaint | Painting | Basical price and how to pay | |

|---|---|---|---|---|---|---|---|---|---|

| CHERUBIM | Road Track, Randoneur, Gravel road, MTB, Mini-vélo etc. | steel | Japan and countries where there is no distributor: In person, by email or by video conference system We have distributors in Indonesia, Philippines, Thailand and Canada. |

Japanese, English | In house painting and outsourcing | ■ Price incl. VAT of the whole road bike frame (Columbus tube): 451,000 JPY (disc brake), 418,000 JPY (rim brake). PUMA (original KAISEI CHERUBIM tube) Price incl. VAT of the whole frame: JPY 396,000 (disc brake), JPY 363,000 (rim brake) SERENA Disc (original KAISEI CHERUBIM tube) Price incl. VAT of the whole frame: 396,000 yen (disc brake specification) The three models above are equipped with tapered carbon forks. STICKY (KAISEI CHERUBIM Original Tube) Price incl. VAT of the whole frame: 341,000 JPY (rim brake specification) Equipped with a 1 inch carbon fork. R2 (KAISEI CHERUBIM Original Tube) Price incl. VAT of the whole frame: 363,000 JPY (rim brake specifications) Equipped with a 1-inch chromoly bent fork. ■Tourer Super Touring (original KAISEI CHERUBIM tube) Price incl. VAT of the whole frame / 363,000 JPY (rim brake specifications) Equipped with 1-inch chromoly bent fork Gravel track Gravel Disc (KAISEI KELBIM Original Tube) Price incl. VAT of the whole frame / 418,000 JPY (disc brake specification) Equipped with a tapered carbon fork MOUNTAIN BIKE ENDEAVOUR disc (Columbus tube) Price incl. VAT of the whole frame / ¥385,000 (disc brake spec.) Without fork ■ Small diameter bike CR Disc (original KAISEI Kerub tube) Price incl. VAT of the whole frame/396,000 yen (disc brake spec.), 363,000 yen (rim brake spec.) Equipped with 1-1/8-inch chromoly fork ■ Track Price incl. VAT of the Triple Crown frame set/330,000 yen Equipped with a 1-inch chromoly bent fork All prices above are base prices. Prices vary depending on craftsmanship and paint specifications. See below for detailed specifications. http://www.cherubim.jp/wp-content/uploads/2022/02/fbb19accd4574f27917543293cfbc6a2.pdf Payment methods Domestic: Bank transfer, Paypay, various credit cards. Overseas: Paypal supported. |

|||

| Dobbat’s | route, piste, tandem, VTT, vélo de gravel et sportif Veuillez contacter aux constracteurs. |

acier | potence originel | Veuillez visiter et consuler les arisants directement concernant mesure ou comment vous utilize votre vélo. | japonais et anglais | un an | disponible repeindre et reparation | Sous-traitance de la fabrication de peinture Milkyway ( Osaka ) | Route prix TTC Succeed de 242,000 yen avec fourche acier Succeed Disque de 242,000 yen sans fourche Phoebe de 266,200 yen avec fourche en acier Willow de 290,400 yen avec fourche en acier Scimitar de 193,600 yen avec fourche en acier Scimitar Disque de 233,200 yen sans fourche Gravel road Timber de 242,000 yen sans fourches VTT MountainHigh de 338,800 yen avec fourche en acier Equip de 242,000 yen sans fourche |

| EQUILIBRIUM | ■Stock model Brutalist (all road) E1 (road) E1 disc (disc road) Full-order models Road, all-road and other models |

Material of frame / Steel, stainless steel, titanium, carbon (hybrid). Manufacturing process / Brazing (lugs, lugless, fillet), Tig welding. |

Stems, carriers, etc. can also be manufactured (steel, titanium). | Face-to-face ordering at the workshop is encouraged. If this is not possible, orders can be placed and discussed by e-mail, telephone or video chat. A deposit of 200,000 yen is required at the time of ordering. Balance due on completion. |

Japaese, English | Enquiry required (depending on when ordered). | Outsourcing for general painting In-house for graphics by titanium anodised |

[Order models] As of December 2021 Road rim brake models: price including tax / from ¥363,000 Steel tubes (Columbus Spirit/Life/HSS etc.), Envy or Columbus forks, Single colour paint included. Road disc brake models: from ¥396,000 incl. tax Steel tubes (Columbus Spirit/Life/HSS etc.), Envy or Columbus forks, Single colour paint included. Road stainless steel rim brake models: from ¥440,000 incl. tax Steel tubes (Columbus Xcr, KVA Stainless), Envy or Columbus forks, Single colour paint included. Road stainless steel disc brake models: from ¥473,000 incl. tax Steel tubes (Columbus Xcr, KVA stainless steel), Envy or Columbus forks, Single colour paint included. Road titanium rim brake models: from ¥583,000 incl. tax Steel tubes (Dedachai/Reynolds Double Butted 3AL-2.5V), Forks Envy or Columbus, Paint estimate separately. Anadized logo included. ■Road titanium disc brake models: price including tax / from JPY 605,000 Steel tubes (Dedachai/Reynolds Double Butted 3AL-2.5V), Envy or Columbus forks, paint quoted separately. Anadized logo included. Payment/Cash, bank transfer, credit card. |

|

| MAKINO | Road, Track, Mini-vélo, Randoneur and others | steel | mudguards pair (including modification): from ¥16,500 (incl. tax) Carrier fabrication (one-off): From ¥55,000 each front and rear (incl. tax) |

When placing a new order, it is fundamental that you visit our shop in person for measurements and consultation. For second and subsequent orders, we accept orders and consultations by telephone, fax or e-mail based on the frame you have previously ridden. We also have distributors. MAKINO distributors TAKENAKA https://www.facebook.com/BicyclesTakenaka 28-2, Imadegawaagaru omotemachi, Tearamachi dori, Kamigyo ward Kyoto city 602-0825 Japan TEL+81-75-256-4863 Amano Cycle 143-2, Ebisu, Kamisuketou machi, Tokushima city,Japan TEL+81-88-653-6736 Cycle & Auto Sakai 4-7-8 Shimo Emorimachi, Fukui city Japan TEL+81-776-34-4001 |

Japanese |

Important notice regarding delivery times. Thanks to the large number of orders we have received, the number of orders remaining far exceeds our annual production capacity. We are working hard to improve delivery times and shorten them considerably, but there are cases where delivery times are unpredictable due to shortages of the base material used or the paintwork. We would like to ask you to place your order as soon as possible, especially if you are preparing for an entrance examination for a KEIRIN racer training school or if you have a race you would like to attend with your new bicycle. We receive many requests such as 'I need it in time for the next exam' or 'I broke my bike in a crash and now I have nothing to ride', but we are unable to respond to these requests as it would delay the delivery dates of other customers even further. We are doing our best to produce the product, so we ask for your understanding. |

Repairs and repainting of second-hand frames are only available on request and with the permission of the person who ordered directly from us. | Repairs and repainting of second-hand frames are only available on request and with the permission of the person who ordered directly from us. | Track and road basic specification: from ¥ 193,600 (incl. tax, head parts, single colour paint) Sportif, Randonner, camping bike, etc., mutguard, carrier compatible frames Basic specification: from ¥215,600 (incl. tax) |

| Panasonic | ■ Custom control / Road, endurance road, cyclo-cross, adventure, track. Select the frame seat tube length in 10 mm increments between 430, 460 and 610 mm. The geometry is predetermined for each size. ■ Full/track order. |

Material / Steel, titanium Manufacturing process / Brazing (horned steel), Tig welding (titanium) |

Front repair forks can be ordered. | Ordered through a Panasonic CycleTech contracted outlet shop. | Japanese | Custom order / in hand within a few weeks of order Full order / about a month and a half |

not availabel | interne paint | Base price: Titanium road frame FRTC23 from ¥294,800 (incl. VAT), steel road frame FRCC43 from ¥96,800 (incl. VAT) Payment method: consult a retailers. |

| Per Gita | to consult with the frame builder | material/ steel fabication mode /brazing(lug、filet) |

luggage carrier and others | Order by visiting the shop. The owner can participate in the production process. Knowing what is being made gives a picture of the finished product. | Japanese |

a year | Repairs, repainting and restoration possible. Please consult us. | outsourcing | Price including tax / ¥ 200,000 (a frame without plating) The details of the production can be discussed with a budget offer. |

| RAIZIN | ロードバイク、小径車、MTBほか要相談 | 素材/スチール 製法/ろう付け(ラグド、ラグレス、フィレット) |

オリジナルキャリア、ステム他応相談 | 基本は来店による対面注文。代理店である自転車専門店を通じての注文も可能 | 日本語 | 平均3ヶ月 | 可(応相談)、レストア可能 | 外注 | 完成時に現金による支払い。または振り込み |

| RAVANELLO | Road, track, randonneur, mini-vélo and others tailored to the rider's wishes. Tandems can also be ordered. | Steel, aluminium, carbon. *Aluminium and carbon are manufactured in Italy. |

Carriers can be ordered. Any manufactured in consultation with the builder. | Face-to-face sales by visiting a shop, orders can also be placed by email | Japanese, English, Italian | 3-6 months |

repair and repaint are available. regarding restauration, please consult with the builder |

outsoucing | price including tax ■Road models Equipe 022: ¥160,000 (KAISEI 022), ¥180,000 (Prestige) Equipe Spirit: ¥260,000 yen *Carbon fork. Equipe Spirit Lug: ¥205,000 *Fork also made of steel. Equipe SAT: ¥270,000 *Carbon fork. Competition: ¥160,000 (KAISEI 022), ¥180,000 (Prestige) Equipe Dedachai SC61.10A: Negotiable *Aluminium frame Equipe Carbon: Negotiable *Moulded carbon frame ■Track racers Equipe Pista 022: ¥160,000. Equipe Pista 022 oversize: ¥190,000 *Carbon fork Tandem Tandem road Tandem Pist ■Cycling Touring: ¥170,000 Sportif: ¥170,000 Mini velo: ¥150,000 yen City cycle: ¥140,000 yen |

| TOEI | touring type (randoneure) , road bike | steel | delivery periode: 3-6 months | price only frame ■ touring type:155,100 yen including tax ■ road bike: 172,700 yen including tax |

Depending on the ordering party's riding style, build and leg strength, the frame builder selects the most suitable pipes from the various frame tube manufacturers and combines them to create the frame.

The following tube manufacturers are available in steel tubing.

1. Columbus (Italy)

https://www.columbus1919.com/it/

2. Reynolds (UK)

https://www.reynoldstechnology.biz/

3. Dedachai (Italy)

4. Kaisei (Japan)

5. Tange (Taiwan) *Former Tange Ironworks

https://www.tange-design.com/index.php

6. KVA Stainless (USA)

http://www.kvastainless.com/

7. True Temper (USA)

8. eco (Taiwan)

Other materials include titanium and carbon (often in combination with metal tubes).

Frames are essentially made of metal materials by welding. Two main types of welding are used. One is brazing, in which brazing material is poured between base materials (e.g. tubes) to join them. The other is 'Tig welding' (a type of arc welding), a type of fusion welding in which the base material is melted by heat.

There are two types of 'brazing'. Lugless, where the base metals are brazed together using solder, and lugged, where the joint is made using a jointing member called a lug. In the case of lugless joints, the joints are specially "filleted" by adding more wax to the joint to give it a smooth silhouette. Lugged rugs come in a variety of different types in terms of their shape, which can also be chosen according to the user's preference when ordering a frame. The same lug design can also be altered by the builder's process.

Both lugged and lugless lugs are said to be well made, with no significant difference in strength.

The work of the people featured on this website is frame building. The focus and specialities vary from brand to brand, but basically any type of road bike, track bike, cyclo-cross, gravel road, MTB, randonneur, folding bike, small bike, tandem, etc. Any frame builder has the technology to make any type of bike. We then design the geometry, combine the pipes and weld them together to create the optimum frame for the user's specific needs, abilities and preferences.

The advantage of a custom-made frame is that it can meet the user's requirements in detail, but it also puts the rider in the best position for the bike. Unlike mass-produced frames, which are limited in frame size, a bespoke frame does not rely heavily on stem or seapost adjustments, but rather achieves the ideal position on the bike (centre of gravity and weight distribution), while achieving the optimum riding position. This is a major reason why custom-made bicycles are said to "ride as if they were your own limbs".

Wheels are the same rank as the frame and are the parts that control the performance of the bicycle. Therefore, even with the same frame, just changing the wheels can drastically change the way you ride.

In the past (around the 1990s), the most common type of wheel was called 'hand-assembly', in which the rim, hub and spokes were selected individually and assembled at a bicycle shop. Since the 2000s, however, it has become more common to use the 'complete assembly' type, in which each component is specially designed by the wheel manufacturer for that model and assembled at the factory, and performance has improved dramatically.

Of course, hand-assembled wheels are still available, and are still very popular because they allow the user to customise specifications, rigidity and ride comfort to suit his or her needs and preferences.

Along with the growing share of fully assembled wheels, carbon rims are the mainstream for high-priced wheels for racing. Aluminium rims are mid- to low-end models.

Bicycles are called 'silver wheels', but that is now a thing of the past. This is because most wheels now have a black appearance, including carbon wheels. This is true not only for wheels but for parts in general.

The collection of parts other than the wheel, handlebar and saddle area is called a component (compo). Components today, as typified by Shimano, have standardised standards and functions for each manufacturer, so there is almost no interchangeability between other manufacturers, such as Sram and Campagnolo. Even within the same manufacturer, there are often incompatibilities depending on the grade, year and number of gears in the rear.

Shimano, Sram and Campagnolo offer total components from the drive to the braking system, while other parts manufacturers have basically developed products that are compatible with these three companies.

Until the mid-1980s, the structure and function of the parts were simple, so other companies were compatible with each other, and users could mix and match manufacturers to suit their preferences. Today, however, only a very limited number of parts (e.g. cranksets and brakes) are flexible.

Tyres are important parts. It is the only part in contact with the road surface and is the source of the bicycle's manoeuvrability, driveability and braking performance. Different tyre types, widths, weights and tread patterns give different riding feelings. The feeling also depends on the air pressure. Experienced drivers adjust the air pressure within a fine range of 0.2 to 0.5 Bar depending on road conditions and other factors, in pursuit of the optimum feeling.

Currently, the most common type is the clincher, which can be either 'tubed' or 'tubeless'. Tubulars are also used for road racing, which are lightweight, supple and still light to ride.

Until a few years ago, all-black was the predominant colour, but now the brown-sided (skin-side) type, which was the standard from the 1980s to the mid-90s, is also back in popularity.

There are so many different types of frame colouring that it is difficult to decide. But it is the most important factor in determining the look of the bike.

Owners are free to choose from multiple colour combinations, chrome (which can be difficult to achieve these days), colour blurring, mesh, etc. It is also possible to repair or repaint the paint if it peels off during use, such as on a ride around the world. If the frame is brought to the builder who ordered it, it will be repainted beautifully, including decals, so it will look as good as new.

A different colour will give it a fresh new look. At that time, you can also ask for customisation, such as having new braized-on parts.

The choice of colours for parts is much more limited than in the past. However, some third-party metal parts are anodised for a more colourful look. Head parts, hubs and other parts can be used as accent colours.

Participation in this website is free of charge for the time being.

You can post texts, photos and video clips. There is a limit to the amount of text that can be published. We will translate the texts into English, French and Chinese and publish them on our website as well as on social networking sites.

If you find any errors in the content, please point them out to us. We will correct them as soon as possible.

Please note that, in principle, we do not provide agency services. It is possible (for a fee) to provide advice on both or either sides of an individual order after consultation.

There will be a separate charge for publication on the pages that feature our topics.

Thank you for your continued support of CYCLING LAB.

1Born 962 in Miyagi Prefecture.

Started cycling at the age of 10. In junior high school, saw an article on the Tour de France in the weekly pictorial magazine Asahi Graph and decided to take up road racing.

Rode as an athlete at high school, university and in the business world. Participated in inter-high school, inter-college and national inter-college athletics (in the inter-college, he finished sixth in the points race in 1985) and also competed in the International Cycle Road Race, the predecessor to the Tour of Japan (39th in Tokyo).

After graduating from Niigata University, he worked for a bank and competed as a businessman. In 1991, he attended the French Cycling Federation coach training course.

After returning to Japan, he became a JCF 1st class referee (road, track and cyclo-cross) in 2001. He has been active in domestic UCI races, including the Japan Cup, mainly as an announcer and radio tool in foreign languages.

| Company name | Cyclinglab.incorporated |

|---|---|

| Company's Foundatin | April, 2018 |

| Chaiman and Co-Representative | Tomoya TAKEDA |

| Head Quoter | 26 Nakamikado-nishi-machi, Nishno-kyo, Nakagyo ward, Kyoto city, Japan |

| Tokyo office | 1-23-6-903, Sakaecho, Higashimurayama city, Tokyo Japan |